HVAC Machinery

Angle BendingLearn More

Roundo, Offered by Trilogy Machinery

- Formed in 1964, Roundo offers the largest selection of angle bending machines in the market

- Over 25 different standard sizes, starting with the R-1, the smallest machine, to the R-21S, the strongest section bending machine available

Beading Learn More

Lockformer 6016 Beader

- Only one operator needed to produce SMACNA-approved beads 4 to 5 times faster than cross braking

- Forms five beads on 12" centers, adjustable to 1/8" depth

- Up to 5' material with a 16 ga maximum capacity

- 1 HP, 115/230 volts, single phase

Brakes Learn More

Roto-Die Hydraulic Bender

- All basic metal shapes formed without die change or major adjustment

- Precision depth-of-stroke indicators permit recording initial settings for repeat reference

- Parallel bed and ram assures multiple precision bending over the entire length of the bed without adjustment of truss bars and rods

- Full wrap-around box and duct forming from either end of the machine

Roto-Die Hydraulic Bender

- The U48-16 heavy-duty bench brake is suitable for box and pan straight bending in up to 16 ga mild steel

- Features a removable apron angle and apron insert permitting ¼" reverse bends in lighter material

- Standard equipment includes an apron, stop rod for repeat bends, extension handles, and a counterweight

- Bending length: 48.25"

- Optional stand available

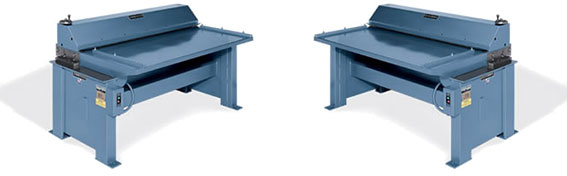

Tennsmith Box and Pan Hand Brake

- Ideal for both box and pan and straight bending in hot and cold rolled plate, stainless steel, aluminum, and heavy plastic

- Features a removable apron insert for 1/4" bends in lighter material

- Upper leaf adjustment screws feature thrust bearings to prevent upper leaf creep

- Ductile steel clamp handles, heavy counterweights, and apron stop rod maximize easy operation

- Capacity: 12 ga mild steel and 16 ga stainless steel

- Bending length: 48.25"

Tennsmith Heavy-Duty Hand Brakes

- Designed for long service and accurate bending

- Welded steel plate construction, heavy truss rods and braces provide strength and durability

- Provide the rigidity required for upper leaf adjustment without the use of wrenches

- Equipped with thrust bearings, the upper leaf adjustment screws permit quick, accurate alignment for different material thicknesses or radii

- Available models: 8 x 18 ga; 8 x 16 ga; 10 x 18 ga; 10 x 16 ga, and 10 x 14 ga

Tennsmith Universal Hand Brake

- Designed to provide forming capabilities for complex parts such as transverse duct, down flanged parts, as well as architectural sheet metal and signage applications

- Truly a universal hand brake that allows for the removal of upper and lower segments of fingers

- Capacity: 16 ga mild steel and 20 ga stainless steel

- Bending length: 72"

CNC Brake FormingLearn More

Haco Press Brakes

- Haco is a world-class manufacturer of press brakes

- Hydraulic machines serve conventional applications

- Multi-axis CNC models offer automatic crowning and sheet followers requiring absolute precision, operator efficiency and safety

Coil ProcessingLearn More

Formtek, a Mestek Company

- Formtek offers a variety of metal forming and coil processing solutions

- Provide cut-to-length lines, multi-braking lines, slitting

- Metal building and metal building products available

- Appliance and metal furniture lines available

Clinching MachinesLearn More

Norlok Surelok III

- Clinching machine is air powered, requires no electrical hookups, and can produce pitch pockets, conductor heads, and virtually any shop fabbed accessory without the use of pop rivets, screws, and caulk

- Versatile fastening of materials from as thin as 32 ga up to 14 ga thick without drilling or use of fasteners

- Available in 18" or 25" throat depth

Custom/HVAC RollformingLearn More

Pittsburgh Lock Model 14-16-18

- Seven forming stations with two forming positions

- One station performs the Pittsburgh Lock, while an auxiliary or outboard position has the ability of forming up to 8 optional profiles

Pittsburgh Lock Model 24

- Compact and light enough to be taken right to the job

- Ideal for 24 ga materials or lighter

- Optional auto-guide power flanging attachment which will create the right-angle flange

- Optional stand available

Pittsburgh Lock Model 20

- Practical lock forming machine

- Available with optional flanging attachment

- Auxiliary rolls/options: double seam rolls, drive cleat rolls, and straight right-angle flange rolls

Lockformer Auto-Guide Flanger 16-18

- Auto-guide feature automatically controls the forming of a right-angle flange

- Two flange heights available: 3/8" or 1/4"

- 16 ga maximum

- 3/4 HP, 115/230 volts, single phase

TDC Rollformer

- 14 stations standard

- Rollforms flanges on transverse duct ends

- Formed on the machine's left-hand auxiliary, the TDC flange has unique, snap-on corners that eliminate spot welding

- Optional rolls are available for Pittsburgh, Z-Bar, and TDC clip

TDC V Rollformer

- 12 forming stations and produces TDC flanges at speeds of up to 50 feet per minute

- Industrial motor and high precision bearings

- Heavy-duty 3-zone chassis

- Plate head and hardened and ground roll shafts

- Optional rolls are available for TDC clip production (no lance kit available)

TDC V Rollformer

- 12 forming stations, produces TDF flanges at up to 60 feet per minute

- Industrial motor and high precision bearings

- No adjustments necessary when going from 26 gauge to 18 gauge material

- High-yield and tensile strength shafts

- Optional clips are produced inboard allowing for optional tooling on outboard shaft

- Machine is driven by an oil filled, sealed, gear reducer, direct coupled to the main motor reducing noise (below OSHA limits)

Engel HB-1640-WT Rollformer

- 16 station TDF rollforming machine with a rated speed of 75 feet per minute

- Capacity: 16–26 gauge, no adjustments required from 18–26 gauge

- Machine gears are large six pitch heavy-duty style allowing the machine to run well below OSHA limits

- Includes snap flange feature

- Extended roll shafts allow for adding optional roll sets

Iowa Precision Dual Head Cornermatic

- Automatically inserts and crimps specially designed TDC/TDF style corners in seconds

- Allows for a complete duct section with eight corners to be inserted and crimped in less than 60 seconds with virtually no operator exertion

- Cornermatic corners are inserted square and fully crimped every time. There are no changes required when inserting corners in 18-26 gauge duct

- Pit-operated machine requires only compressed air and 1ph, 110v current to operate

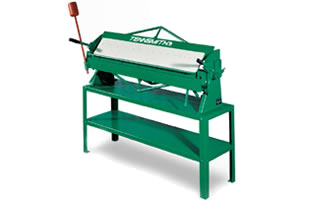

Lockformer Vulcan 1600 WaterJet

- Designed with traditional Lockformer quality and reliability to eliminate the duct liner bottleneck in most shops while dramatically reducing labor

- Standard table size is 5' x 10' but can be ordered up to widths of 6' and lengths of 20'

- Rugged and precise table operates at a high rate of speed thus improving efficiency and productivity

- 50,000 psi intensifier pump easily cuts through fiberglass and neoprene insulations while reducing airborne fibers in the shop atmosphere and environment

- Equipped with VSII software, long recognized as the most user-friendly platform

Duct Connector MachinesLearn More

Lockformer Cheek Bender

- Two-way trunnion ensures perfect bends

- Mounting bolts

- 20 ga

Lion Pneumatic Open Throat Cleat Benders

- Lightweight

- Pre-formed ducts and flats

- Mild steel capacity 20 ga and lighter

- Bend width 7/16" or 1/2"

Lion Pneumatic Closed End Cleat Folder

- Heavy-duty

- Table height designed to accommodate large preformed ducts or flats

- Mild steel capacity 18 ga and lighter

- Bend width 7/16" or 1"

Lockformer 8900 Cleatformer

- Designed for extra-high-speed production of "S" cleats

- Nine forming stations

- 22–28 ga for "S" cleat operation

- Other choices of profiles available for mounting on the auxiliary shafts

- 5 HP, 230/460 volts, 3 phase

Lockformer Triplex Cleatformer

- Nine station machine that incorporates tri-plate construction and reinforced flat "S" cleat

- Extended shafts on both sides accommodate many other sheet-edge operations including the 20 ga Pittsburg Lock and the Button Punch Snaplock

- 22–28 ga for "S" cleat operation

- 20–26 ga for drive cleat operation

- 5 HP, 230/460 volts, 3 phase

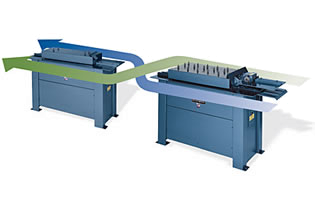

Lockformer Cross-Over System

With this method of in-line production, a machine operator can eliminate:

- Turning a sheet metal blank around

- The need to bring long duct sections around the machine to form the second profile

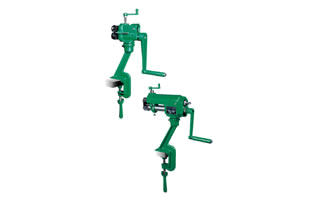

Tennsmith Cleat Bender

- Tennsmith Cleat Bender

- Manually operated tools form uniform drive cleat edges on rectangular ductwork in seconds without set-up or adjustment

- Upper handle forms the cleat and the lower handle opens the tool for easy removal of the material

- Heavy cast iron and fabricated steel construction provides long life and trouble-free operation

- Three models to choose from, all with 20 ga capacity

- Optional stand available

Duct Forming and FabricatingLearn More

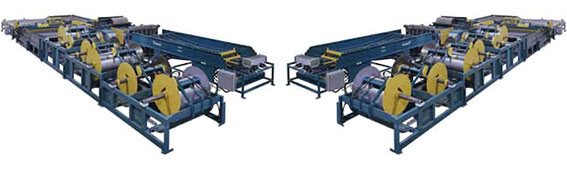

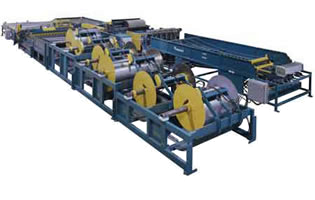

Iowa Precision Pro-Fabriduct:

- Produces commercial and residential ducting

- Modular design with 11 integrated flexible workstations

- "U" or "Z" configurations to optimize floor space

- Forms Pittsburgh, snap-lock, TDC, slip and drive seams and joints

- Process flat sheets, 4-piece duct, "L" duct sections, "U" duct sections and wrap around duct sections

Duct Seam ClosingLearn More

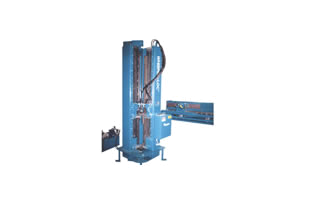

Iowa Precision Whisper-Loc

- Vertical Pittsburgh closure machine for closing longitudinal seams on rectangular duct

- Adjustable for duct made from 36", 48", 60", or 72" coil width, and in gauges 26 to 18

- Accommodates duct with various end-joining methods such as raw, slip and drive, and most transverse flange systems

- 1 HP, 220 volts, single phase

Lockformer TDC Corner Cadet

- Automatically inserts and crimps specially designed TDC/F corners

- Handles virtually every style of duct

- Works with multiple types of fittings

- Portable and lightweight

- 18–26 ga capacity

Ductboard GroovingLearn More

Glass Master SG-220 Ductboard Grooving Machine

- A standard-duty, high capacity model with multiple upper and lower drive rollers

- Sturdy tubular steel frame

- Foot-actuated switch for safer, more dependable operation

- Includes seven tools configured for 1" or 1.5" thick ductboard; 2" tooling available

Edger Learn More

Lockformer Easy Edger

- Turn perfect flanges on elbows or other curved fittings

- No gauge to set

- Hand clamps to any bench

- 20 ga maximum

IronworkersLearn More

Ironworkers

- Sunrise hydraulic ironworkers are designed with multiple functions to save labor, time, energy and cost

- Meet the diversified needs of the metal fabricating industry

- Punching, notching, and shearing work stations equipped with specially designed hold-downs to ensure safety while providing precision and ease of use

Liner SizerLearn More

Duro-Dyne LS5 Liner Sizer

- Accurately slits and cuts insulation

- Accommodates material from thickness of ½" to 2"

- Cross cutting insulation can be done from either side due to the swivelmounted 36" long handle

- Can be mounted on a table or used with the supplied Duro-Dyne frame

Metal FormingLearn More

Schechtl Folder

- These machines can make virtually any shape the architectural sheet metal contractor, sign contractor, job shop, or precision manufacturer can dream up

- Produce everyday parts like copings, gravel stops, gutters, and downspouts, plus complex cornice work, unlimited sign profiles, and even complex boxes

- Bending lengths of 40", 60", 80", 100", 122", and 159"

- Machines with maximum bending capacities from 22–9 ga

- Various rectangular back gauge shapes and a special 120" J-shape

NotchersLearn More

Lockformer TDC Notcher

- Gang-notch sheet metal hydraulically up to 600% faster than by hand

- Hydraulic shut-off valves provide quick individual notching head control

- Measuring tape set in the back gauge bar allows instant locating of the heads

- Locking handle aids in the adjusting of the notch depth

Lockformer Speednotch Model 16

- Gang-notch sheet metal hydraulically up to 600% faster than by hand

- Perfect tool for preparing ductwork to receive "S" and other drive connections

- Complete self-containment provides instantaneous setting from the front for up to five notches on materials up to 16 ga with 3.25" to 10' stretch out

PinspottersLearn More

Duro-Dyne FG Mach II Rolling Head Pinspotter

- Hi-power 18 ga capacity with 2" pins

- One adjustment controls weld and dwell times

- Digital function display

- Sleek streamlined frame design with 5' throat

- Posi-Feed weld pin track release system

Duro-Dyne FG Mach I Pinspotter

- Standard 20 ga capacity

- Hi/Lo switch adjusts for gauge thickness and/ or voltage variances

- One adjustment controls weld and dwell times

- Digital function display

- Sleek streamlined frame design with 5' throat

Duro-Dyne MFPT Pinspotter

- Compact design for easy handling

- Standard 8' gun cable and 6' ground cable

- Easy-read weld timer for precise control

- Panel mounted test switch and indicator lights

- Input voltage: 208-230 V 60 HZ single ph

Plasma CuttingLearn More

Lockformer Vulcan 1000D Plasma Cutting System

- User-friendly operator controls and easy-to-use software

- Excellent cut quality and precision on a wide variety of materials

- Patented Hypertherm-shielded nozzle for longer nozzle life and heavier piercing capability

- Vertical dual-cylinder pneumatic torch lifter with adjustable up/down pressure

- Sealed DC servo brushless motor and motor encoders for steady movement of the torch over the entire cutting area

Rotary MachinesLearn More

Empire Power Rotary Machine

- Single bead rolls (3/16", 1/4", 1/2")

- Crimping rolls and combination bead/crimp rolls

- Ogee bead, offset, slitting, and flattening rolls

- Spin-in-collar rolls (single operation)

- Elbow edging

- ¼" #19 flanging rolls

- ½" #20 flanging rolls for max 16 ga MS

Empire Power Rotary Machine

- Model R22, with interchangeable rolls, is a versatile forming tool for the manual performance of numerous sheet metal operations

- Features a solid cast, enclosed frame and smooth meshing machine gears

- Material can be fed through the rolls in either direction by selecting the proper arbor

- Model R24 provides simultaneous crimping and beading on 24 ga and lighter material

- Standard equipment include ogee bead and crimping rolls, spacers, a hand crank, spanner, and bench stand

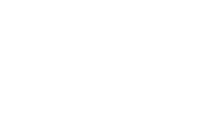

ShearsLearn More

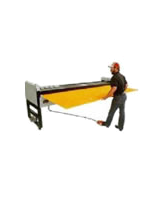

Schechtl Shear

- SMT and MSB shear models come with a unique, full-length telescoping front sheet support that makes it easy for one operator to handle even 5' or 10' sheets

- Adjustable support arms with T-slot and scale, stainless steel, removable and adjustable hollow grip areas for easy handling

- Extended squaring arm with in-laid scale

- SMT 3100 – 10', 16 ga shear (.090" alum.)

- MSB 3100 – 10', 14 ga steel shear (.125" alum)

- MSC 3100 – 10', 11 ga steel shear (.175" alum)

Tennsmith LM1014 Mechanical Shear

- Standard with four-edge, high carbon, high chrome top and bottom blades

- 2x back gauge system allows operator to move the backstop from 0 to 30" in approximately 2 seconds with only two rotations of the handle

- Optional air operated sheet support system is available in two styles:

- System "R" drops the supported material to the rear of the machine

- System "F" returns the supported material to the front of the machine via a front return chute

- Handles 14 ga mild steel up to 121"

- 5 HP, 230/460 volts, 3 phase

Tennsmith Foot Squaring Shear

- Shear frame, bed, and cutter head assemblies constructed of heavy-duty cast iron

- Features tri-action, ground-alloy tool steel blades

- Bed-adjustable lower shear blade and upper blade is adjustable by a truss bar on the cutter head

- Capacity: 16 ga mild steel, 20 ga stainless steel

- Maximum cutting length: 52.25"

Tennsmith Power Squaring Shear

- Combines all the features of the foot shears with the advantage and convenience of hydraulic operation

- Cycles at 60 strokes per minute due to its high quality hydraulic system

- Features include solenoid actuated valve, 3 HP electric motor, 10-gallon tank, with sight gauge and thermometer, pressure gauge, check valve, and industrial quality cylinders

- Capacity: 16 ga mild steel and 20 ga stainless steel

- Maximum cutting length: 52.25"

Tennsmith Mechanical Shear

- Equipped with a standard "GO TO" 30" back gauge system

- The ball screw driven back gauge provides quick, accurate cuts

- Powered by a 12.5 HP gear motor attached to a mechanical linkage for smooth, quiet operation

- Rated at a maximum of 10 ga mild steel and 14 ga stainless steel material with a cutting width of 121"

SlittersLearn More

Wilder Workhorse Power Slitter Model 1624

- 16 ga capacity

- 24.25" maximum slit width

- Motor: 1/3 HP motor

- Speed: 90 sfm

Specifications:

- 20 ga capacity

- 24.25" maximum slit width

- 3/4 HP motor

- Speed: 90 sfm

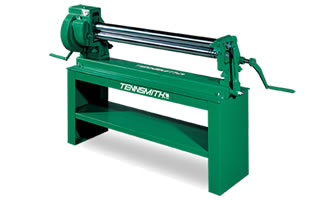

Slip RollsLearn More

Tennsmith Slip Rolls

- An accurate and durable forming tool with precision-turned, ground and polished, high carbon steel rolls with heavy-duty, cast iron end frames, and welded steel base

- Convenient operating features include large roll adjustment screws, scales for speed repeat set-up, and front-mounted handle to lift the upper roll for material removal

- Capacity: 22 ga mild steel

- Forming length: 36"

- Optional stand available

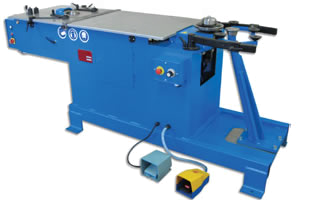

Tennsmith Pinch Slip Rolls

- Heavy-duty production tool for forming curved parts and tubes in 16 ga and lighter sheet metal

- The SR48 roll has three gear-driven rolls that ensure even starting and feeding capacity materials

- All gears are fully enclosed for safety and protection from the elements

- Maximum forming length: 49"

- Optional stand available

Snap Lock MachinesLearn More

Lockformer Button Punch Snap Locks

- Specially designed for commercial and industrial ductwork

- Produces both a receiver lock (inboard rolls) and a button-punched rightangle flange (outboard rolls)

- Two models are available:

- 20 ga (9 station) and lighter material

- 24 ga (7 station) and lighter material

Spiral FittingLearn More

Gore-Max 1.25 Spiral Fitting Gorelocker

- Easy operation allows production of hundreds of fittings per day

- Produces elbows, reducers, end caps, and offsets

- Offers two machine functions in one

- Flanger/Swager will flange one side of a cylindrical gore while swaging the connecting side of the next gore with the simple flip of a switch

- Lockseamer finalizes the operation by closing the seam into a standing rib

- Operations are conducted simultaneously thus increasing productivity

- Produces elbows from 5" to 50", 18 gauge capacity

- Airtight seals eliminate the need for painting, coating, or sealing

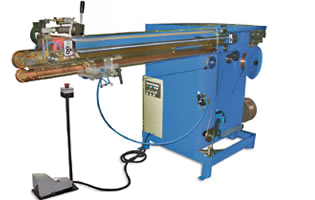

Max Stitch 1.0 Tube Welder

- Maximizes welding production output and quality

- Controlled and consistent longitudinal weld from end to end ensures a remarkable weld every time

- The copper wire conductant will not burn off the galvanized surface like ordinary spot welders

- F¼" overlap provides a consistent, high quality weld while reducing material costs

- Controlled welding current for continuous or alternating welds

- Excellent solution for longitudinal welding of stainless steel tubes

Spiral TubeformerLearn More

Max Stitch 1.0 Tube Welder

- Programmable Logic Controller (PLC)

- Exclusive Spiral Smart Technology (SST) programming provides operators with set up requirements and automatic troubleshooting

- Hydraulically or electric powered for superior speed, strength, and reliability

- Flying slitting device allows for a quiet, gasless, and clean cut of the spiral tubes

- Available in three models with speeds ranging from 210 fpm to 265 fpm